UPVC Column Riser Drop Pipes

Price 50-5000 INR/ Piece

UPVC Column Riser Drop Pipes Specification

- Diameter

- 32 mm, 40 mm, 50 mm, 63 mm, 75 mm, 90 mm, 110 mm, 125 mm, 140 mm, 160 mm, 200 mm

- Sealing Type

- Rubber O-Ring Sealing

- Temperature Range

- 0C to 45C

- Yield Strength

- 39 MPa

- Thread Type

- Square Threads

- Flexibility

- Rigid

- Bend Radius

- Not Suitable for Bending

- Tensile Strength

- 45 MPa

- Coating Type

- Uncoated / Natural UPVC

- Tolerance

- +/- 0.2 mm

- Connection Type

- Threaded Joints

- Product Type

- UPVC Column Riser Drop Pipe

- Material

- Unplasticized Polyvinyl Chloride (UPVC)

- Connection

- Threaded Male-Female

- Shape

- Round

- Standard

- IS 12818 / ASTM D1785

- Surface Treatment

- Smooth Finish

- Outer Diameter

- 32 mm to 200 mm

- Section Shape

- Cylindrical

- Length

- 3 m / 6 m (customizable)

- Thickness

- From 2.5 mm up to 8 mm (varies with size)

- Color

- Blue/White

- Usage

- For submersible pump installation, borewells, irrigation, drinking water supply

- Rated Pressure

- Up to 16 kg/cm2 (varies with size)

- Application

- Borewell water rising, submersible pump riser

- Material Grade

- UPVC, Lead-Free Grade

- Life Span

- Up to 50 years (under recommended operation)

- Corrosion Resistance

- Excellent

- Odor/Taste

- Odorless & Tasteless for Potable Water

- Pipe End Finish

- Precision Machined

- Impact Strength

- High

- Hydrostatic Pressure Test

- Yes, as per IS 4985

- Installation Method

- Threaded with O-Ring Seal

- Resistant to Chemicals

- Yes, to most minerals and ground water chemicals

- Inner Surface

- Very Low Friction/Very Smooth

- UV Resistance

- High UV Protection

- Non-Toxic

- Yes, Food Grade Material

- Density

- 1.4 g/cm3

- Storage Condition

- Dry & Shaded Area

- Fire Resistance

- Self-Extinguishing

UPVC Column Riser Drop Pipes Trade Information

- Minimum Order Quantity

- 50 Pieces

- Supply Ability

- 50 Pieces Per Day

- Delivery Time

- 10 Days

About UPVC Column Riser Drop Pipes

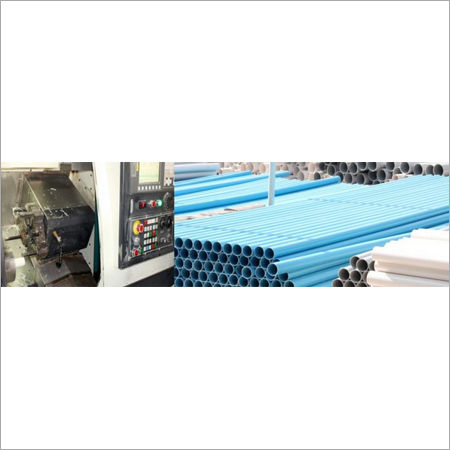

The joint of UPVC Column Riser Drop Pipes has been planned with square threads to guarantee legitimate holding and no difference in slipping. In addition, the threads have high friction on the load that does not open on the steady reverse and forward torque produced by stopping and starting the pump. Our UPVC Column Riser Drop Pipes are made on imported CNC machines alongside high precision tools to guarantee immaculate measurements and great fitment. The threads are tested thoroughly with gauges to ensure 100% precision.

Benefits:

- Long Life

- No rusting, erosion or crumbling

- Low in Weight

- Simple installation

- Cost Saver

- Power-efficient

- 10-80% extra water release

- No Electrolytic deposition

Technical Chart For All Size & Types Of Atul Column Pipes From 1 Upto 5

Size& Type | END Wall Thikness | Barrel Wall Thikness | Efective | Ultimate | Safe Pulling | Safe allowable | Safe Total Pump | ||

Min. | Max. | Min. | Max. | ||||||

1 ND-25 ECO | 3.0 | 3.4 | 1.9 | 2.3 | 3000+10 | 1000 | 700 | 15 | 150 |

1 ND-25 Medium | 3.6 | 4.0 | 2.5 | 3.0 | 3000+10 | 1400 | 770 | 16 | 160 |

1 ND-25 Standard | 4.95 | 5.3 | 4.0 | 4.5 | 3000+10 | 1800 | 1300 | 30 | 300 |

1 ND-32 | 4.8 | 5.0 | 2.8 | 3.0 | 300010 | 1900 | 1100 | 21 | 210 |

1 ND-40 | 5.3 | 5.5 | 3.5 | 3.7 | 300010 | 2500 | 1400 | 21 | 210 |

2 ND-50 | 5.1 | 5.4 | 2.6 | 2.9 | 300010 | 2800 | 1500 | 13 | 130 |

2 ND-65 | 5.1 | 5.4 | 2.6 | 2.9 | 300010 | 3500 | 1900 | 10 | 100 |

3 ND-80 | 5.7 | 6.1 | 3.2 | 3.5 | 300010 | 5000 | 2750 | 11 | 110 |

4 ND-100 | 6.3 | 6.5 | 3.8 | 4.3 | 300010 | 7500 | 4100 | 10 | 100 |

5 ND 125mm | | | | | | | | | |

Medium | 7.3 | 7.7 | 5 | 5.4 | 300010 | 11000 | 6100 | 10 | 100 |

Standard | 10.1 | 10.7 | 7.6 | 7.85 | 300010 | 16000 | 9000 | 16 | 150 |

Engineered Durability and Safety

These UPVC Column Riser Drop Pipes combine high-density, food-grade materials with excellent resistance to chemicals, minerals, and UV exposure. The smooth, precision-finished surfaces ensure low friction, while the self-extinguishing feature enhances safety in critical applications. Certified to IS 12818 and ASTM D1785 standards, each pipe is meticulously hydrostatically tested, ensuring robust performance and a long lifecycle, even in challenging groundwater environments.

Effortless and Secure Installation

With threaded male-female joints and rubber O-ring sealing, these riser pipes deliver quick, hassle-free assembly and superb leak prevention. The standardized square threads and precision engineering facilitate proper alignment, reducing downtime during installation in borewells or submersible pump systems. Their rigid structure and range of available sizes make them suitable for new installations or upgrades.

Ideal Applications and Versatile Usage

Designed to meet the diverse needs of borewell water rising, submersible pump risers, irrigation, and potable water supply, these pipes demonstrate unmatched adaptability. They are odorless, tasteless, and completely non-toxic, making them ideal for drinking water systems. Whether for domestic or agricultural use, they provide a long-term, cost-effective solution across India and in export markets.

FAQ's of UPVC Column Riser Drop Pipes:

Q: How are UPVC Column Riser Drop Pipes installed for borewell and submersible pumps?

A: Installation is accomplished using precision-machined threaded male-female joints with robust rubber O-ring seals, ensuring a secure and leak-proof fit. The pipes are rigid and are connected section by section, typically in lengths of 3 or 6 meters, depending on site requirements.Q: What benefits do these UPVC riser pipes offer over traditional metal pipes?

A: They provide excellent corrosion and chemical resistance, high UV protection, and non-toxicity for safe potable water use. Their high impact strength, low friction surfaces, and lightweight structure result in reduced maintenance, easy handling, and a life span of up to 50 years under standard conditions.Q: When should I select UPVC Column Riser Drop Pipes for water supply applications?

A: Choose these pipes whenever you require durable, corrosion-resistant, and safe options for submersible pumps, borewell water rising, irrigation, or potable water systems-especially in regions with aggressive water or high UV exposure.Q: Where should I store UPVC riser drop pipes before installation?

A: UPVC pipes should be stored in a dry and shaded area to preserve their structural integrity and prevent premature UV degradation, ensuring they remain in optimal condition for installation.Q: What testing standards are these pipes manufactured and tested to?

A: They are manufactured according to IS 12818 and ASTM D1785 standards and undergo hydrostatic pressure tests as per IS 4985, certifying their performance and reliability for demanding applications.Q: How resistant are these pipes to chemicals and environmental factors?

A: UPVC riser pipes are engineered to resist most minerals, groundwater chemicals, and UV exposure. Their non-toxic, lead-free composition and self-extinguishing property further enhance suitability for both potable and industrial water applications.Q: What diameters and lengths are available, and can they be customized?

A: Available diameters range from 32 mm to 200 mm, with standard lengths of 3 m or 6 m. Customization in length can be provided as per the application's needs or project specifications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Agro Pipes Category

UPVC Garden Pipes

Price 50-5000 INR / Piece

Minimum Order Quantity : 50 Pieces

Application : other, Gardening, Domestic, Outdoor Watering

Rated Pressure : 4 kg/cm

Surface Treatment : Other, Smooth Finish

Section Shape : Other, Circular

UPVC Pressure Pipes

Price 50-5000 INR / Piece

Minimum Order Quantity : 50 Pieces

Application : other, Drinking water distribution, agriculture, industrial fluid handling

Rated Pressure : 2.5 kg/cm to 16 kg/cm (Class 2 to Class 10)

Surface Treatment : Other, Smooth, untreated

Section Shape : Other, Circular

UPVC Pipes

Price 50-5000 INR / Piece

Minimum Order Quantity : 50 Pieces

Application : other, Water Distribution, Industrial, Agricultural

Rated Pressure : 2.5 kg/cm to 16 kg/cm

Surface Treatment : Other, Smooth Finished

Section Shape : Other, Circular

UPVC Plumbing Pipes & Fittings

Price 50-5000 INR / Piece

Minimum Order Quantity : 50 Pieces

Application : other, Residential, Commercial, Industrial piping, Water supply

Rated Pressure : 2.5 kg/cm to 16 kg/cm (varies with size/class)

Surface Treatment : Other, Smooth, Plain

Section Shape : Round

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry